|

|

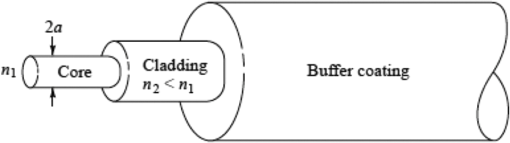

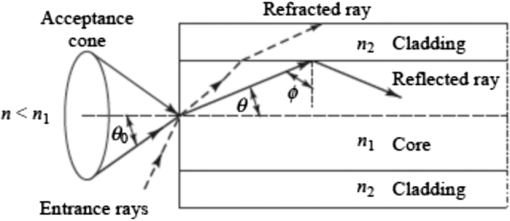

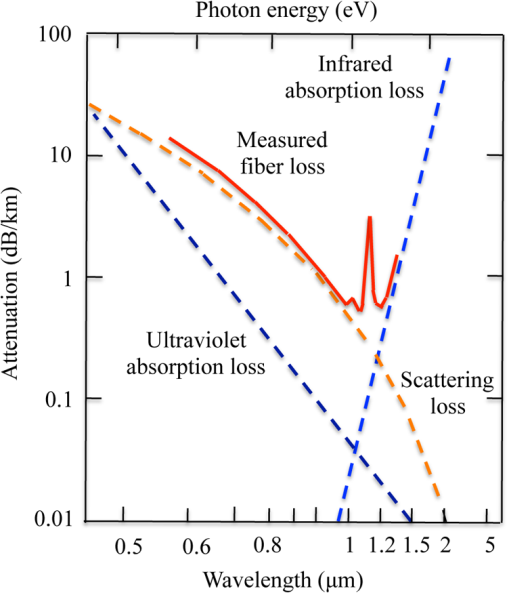

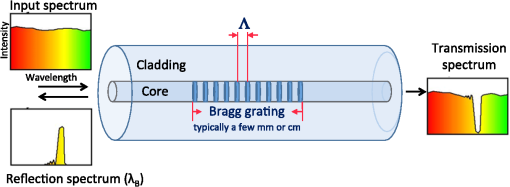

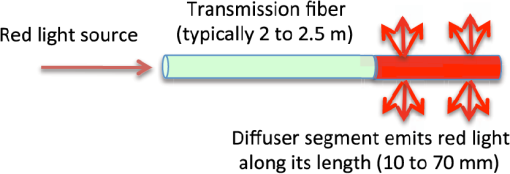

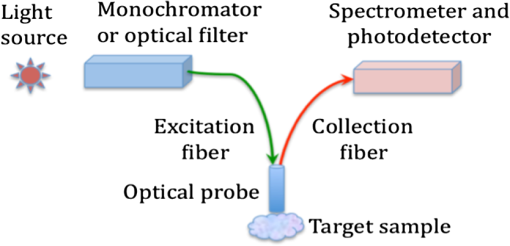

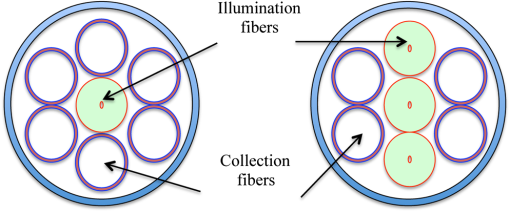

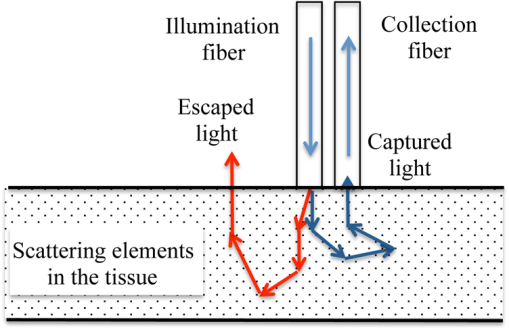

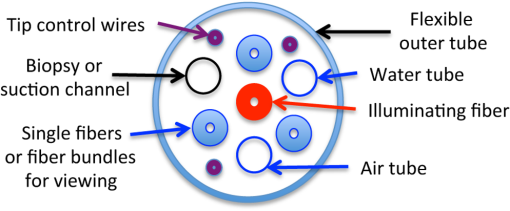

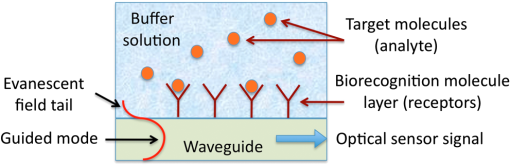

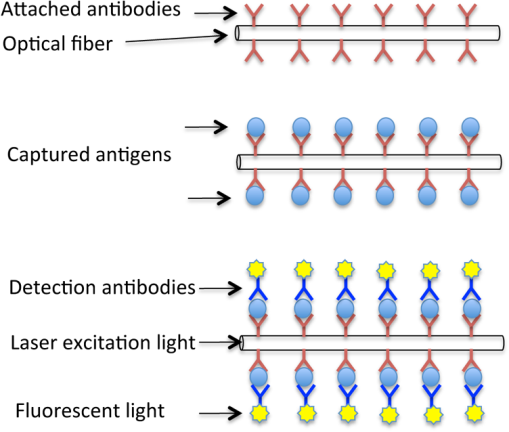

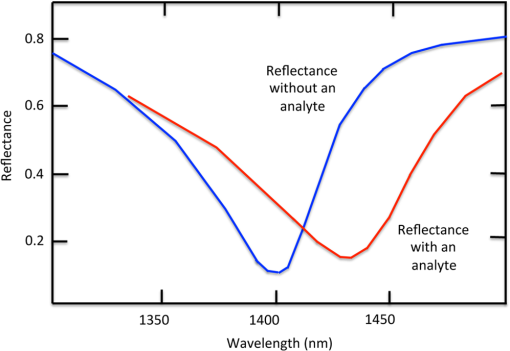

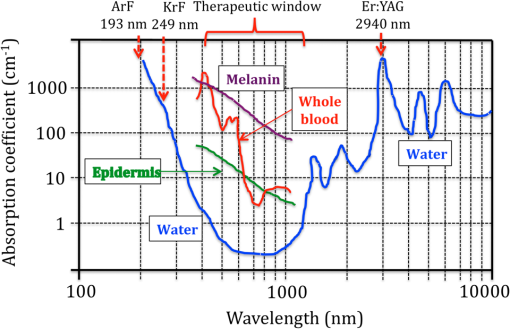

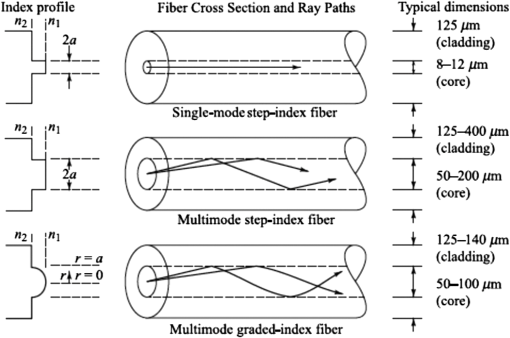

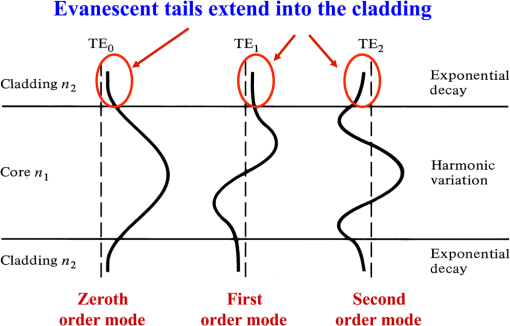

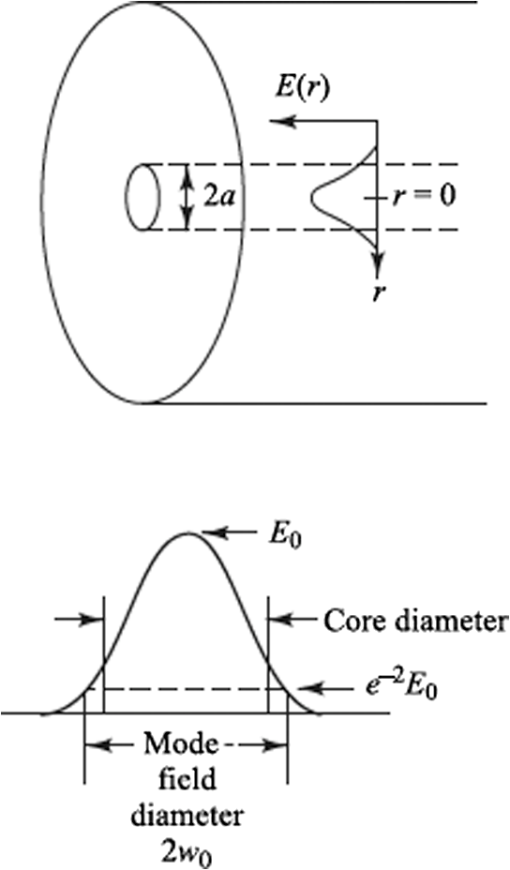

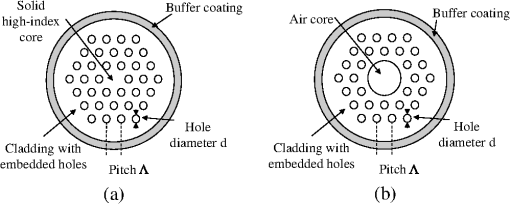

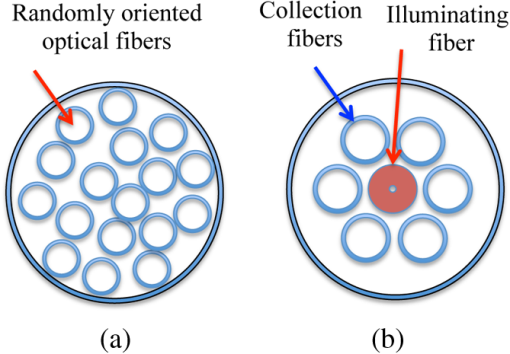

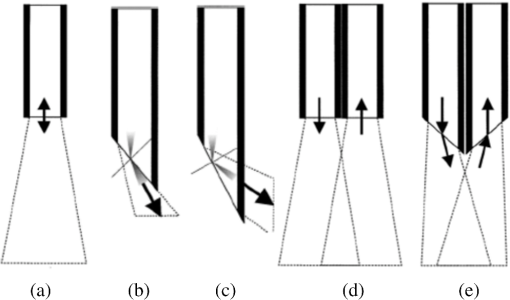

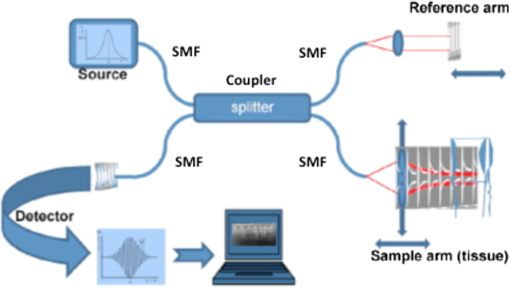

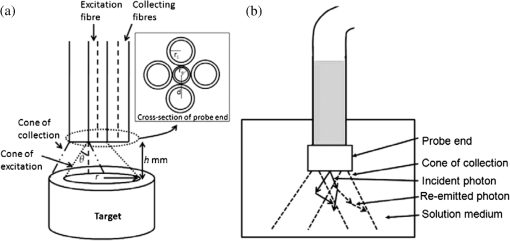

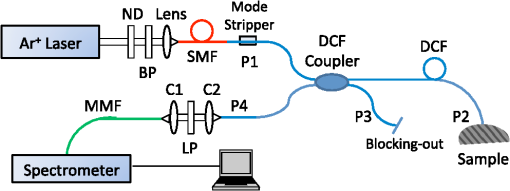

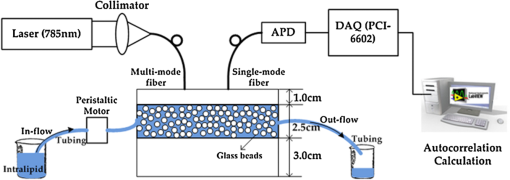

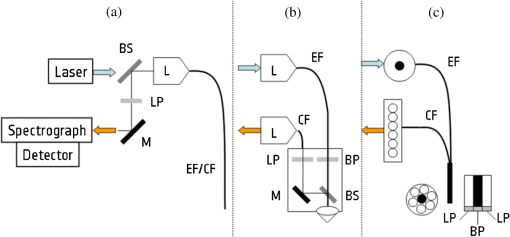

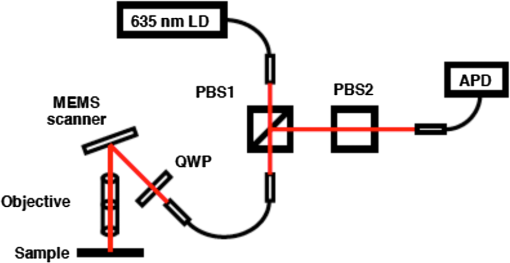

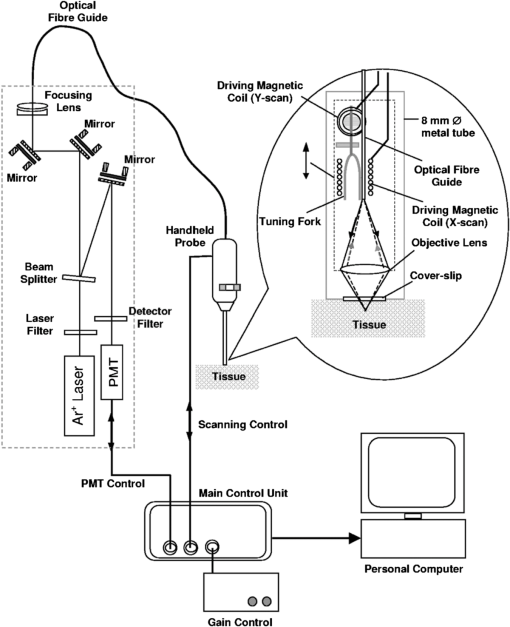

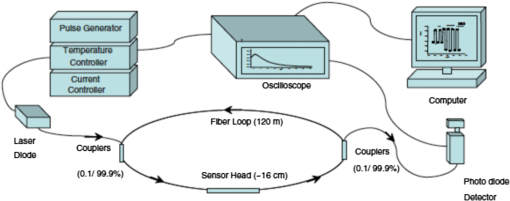

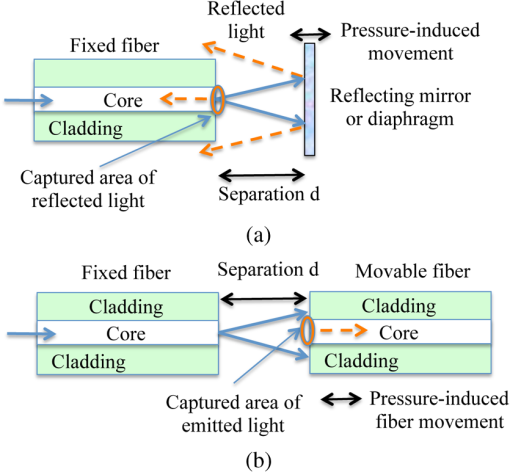

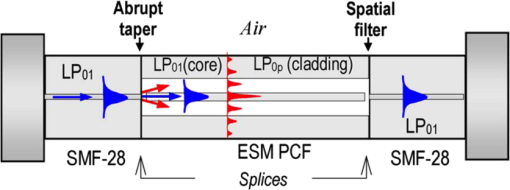

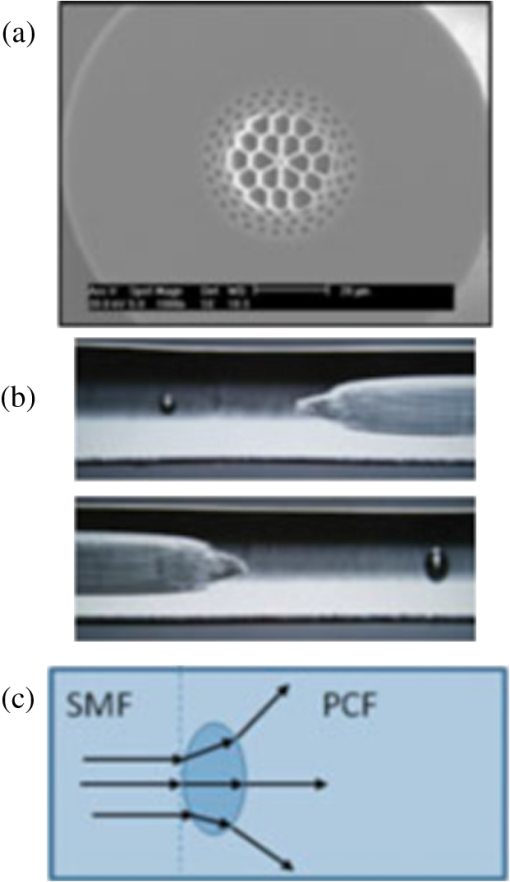

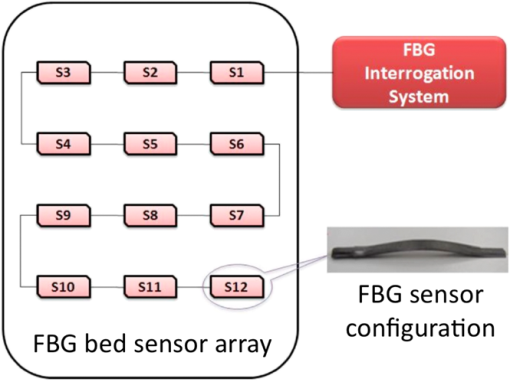

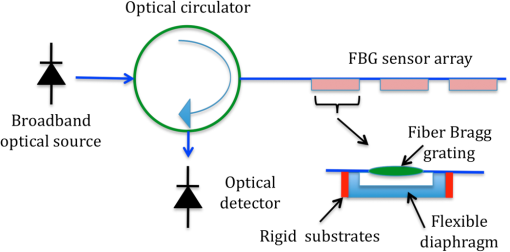

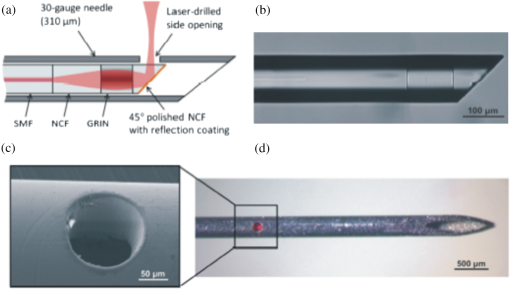

1.IntroductionIn recent years, there has been an extensive and rapidly growing use of photonics technology for basic life sciences research and for biomedical diagnosis, therapy, monitoring, and surgery.1–3 Among the numerous diverse applications are imaging, spectroscopy, endoscopy, tissue pathology, blood flow monitoring, light therapy, biosensing, biostimulation, laser surgery, dentistry, dermatology, and health status monitoring. Major challenges in biophotonics applications to life sciences include how to collect and transmit low-power (down to the nanowatt range) emitted light to a photodetector, how to deliver a wide range of optical power levels to a tissue area or section during different categories of therapeutic healthcare sessions, and how to access a diagnostic or treatment area within a living being with an optical detection probe or a radiant energy source in the least invasive manner. Depending on the application, all three of these factors may need to be addressed at the same time. The unique physical and light-transmission properties of optical fibers enable them to help resolve such implementation issues. Consequently, various types of optical fibers are finding widespread use in biophotonics instrumentation for life sciences related clinical and research applications. Each optical fiber structure has certain advantages and limitations for specific uses in different spectral bands. Therefore, it is essential that biophotonics researchers and implementers know which type of fiber is best suited for a certain application. This paper provides the background that is necessary to understand how optical fibers function, explains various categories of fibers, and illustrates how certain fibers are used for specific biophotonics implementations. To understand when and where to use specific optical fiber types, some background information is presented in Sec. 2 on why various lightwave bands in the ultraviolet, visible, and infrared regions are of interest for biomedical diagnostic and therapeutic implementations. Next, Sec. 3 discusses the fundamental principles for light guiding in conventional solid-core fibers. This discussion will be used as a basis for describing light guiding in other optical fiber structures. In addition, Sec. 3 also describes the optical fiber performance characteristics needed for specific spectral bands. With this background information, Sec. 4 then presents several categories of optical fiber structures and materials that are appropriate for use at different wavelengths. This discussion includes conventional and specialty multimode and single-mode solid-core fibers, double-clad fibers (DCFs), hard-clad silica (HCS) fibers, conventional hollow-core fibers, photonic crystal fibers (PCFs), polymer optical fibers (POFs), side-emitting and side-firing fibers, middle-infrared fibers, and optical fiber bundles. Included in this discussion are the fiber materials that are appropriate for use at different wavelengths. Finally, Sec. 5 describes some examples of optical fiber applications to various biomedical disciplines. 2.Biophotonics Spectral WindowsThis section describes the fundamental background as to why specific lightwave windows are needed to carry out various therapeutic and diagnostic biomedical photonics processes. Having this knowledge allows the selection of an optical fiber whose specification could meet the transmission criteria for carrying out a specific biomedical process. The interaction of light with biological tissues and fluids is a complex process because the constituent materials are optically inhomogeneous. Because diverse biological tissue components have different indices of refraction, the refractive index along some path through a given tissue volume can vary continuously or undergo abrupt changes at material boundaries, such as at flesh and blood vessel or bone interfaces. This spatial index variation gives rise to scattering, reflection, and refraction effects in the tissue.4–12 Thus, although light can penetrate several centimeters into a tissue, strong scattering of light can prevent observers from getting a clear image of tissue abnormalities beyond a few millimeters in depth. Light absorption is another important factor in the interaction of light with tissue, because the degree of absorption determines on how far light can penetrate into a specific tissue. Figure 1 shows the absorption coefficients for several major tissue components. These components include water ( of the body), whole blood, melanin, epidermis, and blood vessels. The wavelengths of interest span the spectral range from in the ultraviolet (UV) to in the infrared (IR). Fig. 1Absorption coefficients of water, hemoglobin (), melanin, and skin as a function of wavelength.  Most tissues exhibit comparatively low absorption in the spectral range that extends from 500 to , that is, from the orange region in the visible spectrum to the near-infrared (NIR). This wavelength band is popularly known as the therapeutic window or the diagnostic window because it enables viewing or treating tissue regions within a living body by optical means. Light absorption characteristics of tissue for regions outside the therapeutic window are important for implementing functions that depend on high optical power absorption, such as drilling, cutting, bonding, and ablation of tissue. A wide variety of optical sources can be used to carry out these functions.1,13–16 For example, as indicated in Fig. 1, UV light from ArF or KrF lasers emitting at wavelengths of 193 and 249 nm, respectively, is strongly absorbed in the surface of a tissue and, thus, can be used for many surgical applications. As an example, in the IR region, the 2940-nm light from an Er:YAG laser is strongly absorbed by osseous minerals, which makes optical sawing and drilling in bones and teeth possible. 3.Optical Fiber Structures and Performance CharacteristicsThis section discusses the fundamental principles for light guiding in conventional optical fibers. Here the term conventional refers to the structure of optical fibers that are widely used in telecom networks. This discussion will set a basis for describing light guiding in other optical fiber structures that are presented in Sec. 4. In addition, Sec. 3 also describes the performance characteristics needed for specific spectral regions, for example, optical signal attenuation, bending loss sensitivity, mechanical properties, and optical power-handling capabilities.17–23 3.1.Light Guiding Principles in Conventional Optical FibersAn optical fiber is a dielectric waveguide that operates at optical frequencies. This fiber waveguide is normally cylindrical in form. It confines electromagnetic energy in the form of light within its surfaces and guides the light in a direction parallel to its axis. The propagation of light along a waveguide can be described in terms of a set of guided electromagnetic waves called the modes of the waveguide. Each guided mode is a pattern of electric and magnetic field distributions that is repeated along the fiber at equal intervals. Only a certain discrete number of modes are capable of propagating along the waveguide. These modes are those electromagnetic waves that satisfy the homogeneous wave equation in the fiber and the boundary condition at the waveguide surfaces. Figure 2 shows a schematic of a conventional optical fiber, which consists of a cylindrical silica-based glass core surrounded by a glass cladding that has a slightly different composition.17–19 The core of diameter 2a has a refractive index and the cladding has a slightly lower refractive index . Surrounding these two layers is a polymer buffer coating that protects the fiber from mechanical and environmental effects. The refractive index of pure silica varies with wavelengths ranging from 1.453 at 850 nm to 1.445 at 1550 nm. By adding certain impurities, such as germanium dioxide (), to the silica during the fiber manufacturing process, the index can be slightly changed. This is done so that the refractive index of the cladding is slightly smaller than the index of the core (i.e., ). This condition is required so that light traveling in the core is totally internally reflected at the boundary with the cladding, which is the physical mechanism that guides light signals along a fiber. The variations in material and size of the conventional solid-core fiber structure dictate how a light signal is transmitted along a fiber and also influence how the fiber performance responds to environmental perturbations, such as stress, bending, and temperature variations. Variations in the material composition of the core give rise to two commonly used fiber types, as shown in Fig. 3. In the first case, the refractive index of the core is uniform throughout and undergoes an abrupt change (or step) at the cladding boundary. This is called a step-index fiber. In the second case, the core refractive index varies as a function of the radial distance from the center of the fiber. This type is a graded-index fiber. Fig. 3Comparison of conventional single-mode and multimode step-index and graded-index optical fibers.  Both the step- and the graded-index fibers can be further divided into single-mode and multimode classes. As the name implies, a single-mode fiber (SMF) sustains only one mode of propagation, whereas a multimode fiber (MMF) contains many hundreds of modes. A few typical sizes of SMF and MMF are given in Fig. 3 to provide an idea of the dimensional scale. MMFs offer several advantages compared with SMFs. The larger core radii of MMFs make it easier to launch optical power into the fiber and to collect light emitted or reflected from a biological sample. SMFs are more advantageous when delivering a narrow light beam to a specific tissue area and also are needed for applications that deal with coherence effects between propagating light beams. The remainder of Sec. 3.1 describes the operational characteristics of step-index fibers, and Sec. 3.2 describes graded-index fiber structures. 3.1.1.Ray optics conceptsTo get an understanding of how light travels along a fiber, first consider the case when the core diameter is much larger than the wavelength of the light. For such a case, a simple geometric optics approach based on the concept of light rays can be used. Figure 4 shows a light ray entering the fiber core from a medium of refractive index , which is less than the index of the core. When the ray meets the fiber end face, it is refracted into the core and propagates at an angle , which is smaller than the entrance angle of that ray. Inside the core, the ray strikes the core-cladding interface at an angle relative to the normal to the surface. If the light ray strikes this interface at such an angle that it is totally internally reflected, the ray becomes confined to the core region and follows a zigzag path as it travels along the fiber. From Snell’s law, the minimum or critical angle that supports total internal reflection is given by Rays striking the core-cladding interface at angles less than will refract out of the core and be lost in the cladding as the dashed line shows. The condition of Eq. (1) can be related to the maximum entrance angle , which is called the acceptance angle , through the relationship where . Thus, those rays having entrance angles less than will be totally internally reflected at the core-cladding interface. Thus, defines an acceptance cone for an optical fiber. Rays outside of the acceptance cone, such as the ray shown by the dashed line in Fig. 4, will refract out of the core and be lost in the cladding.The critical angle also defines a parameter called the numerical aperture (NA), which is used to describe the light acceptance or gathering capability of fibers that have a core size much larger than a wavelength.5,17,18 This parameter defines the size of the acceptance cone shown in Fig. 4. NA is a dimensionless quantity that is less than unity, with values nominally ranging from 0.14 to 0.50. NA is given by The parameter is called the core-cladding index difference or simply the index difference. It is defined through the equation . Typical values of range from 1 to 3 percent for MMF and from 0.2 to 1.0 percent for SMF. Thus, since is much less than 1, the approximation on the right-hand side of Eq. (3) is valid. Because NA is related to the maximum acceptance angle, it is commonly used to describe the light acceptance or gathering capability of an MMF and to calculate the source-to-fiber optical power coupling efficiencies. The NA value is listed on vendor data sheets for fibers. 3.1.2.Modal conceptsAlthough the ray representation gives a general picture of light propagation along a fiber, mode theory is needed for a more detailed understanding of concepts such as mode coupling, dispersion, coherence or interference phenomena, and light propagation in single-mode and few-mode fibers. Figure 5 is a longitudinal cross-sectional view of an optical fiber that shows the field patterns of some of the lower-order transverse electric. The order of a mode is equal to the number of field zeroes across the guiding core. The plots show that the electric fields of the guided modes are not completely confined to the core but extend partially into the cladding. The fields vary harmonically in the core region of refractive index and decay exponentially in the cladding of refractive index . For low-order modes, the fields are tightly concentrated near the axis of an optical fiber with little penetration into the cladding region. Higher-order mode fields are distributed more toward the edges of the core and penetrate farther into the cladding. Fig. 5Electric field distributions of lower-order guided modes in an optical fiber (longitudinal cross-sectional view).  As the core radius shown in Fig. 2 is made progressively smaller, all modes except the fundamental mode shown in Fig. 5 will start getting cut off. A fiber in which only the fundamental mode can propagate is an SMF. An important parameter related to the cutoff condition is the number defined by where the approximation on the right-hand side comes from Eq. (3). This parameter is a dimensionless number that determines how many modes a fiber can support. Except for the lowest-order fundamental mode, each mode can exist only for values of that exceed the limiting value (with each mode having a different limit). The wavelength at which all higher-order modes are cut off is called the cutoff wavelength . For example, if and , then from Eq. (4), with , the cutoff wavelength is . That is, only the fundamental mode will propagate in the fiber for wavelengths . The fundamental mode has no cutoff and ceases to exist only when the core diameter is zero. This is the principle on which SMFs are based.The number can be also used to express the number of modes in a multimode step-index fiber when is large. For this case, an estimate of the total number of modes supported in such a fiber is Because the field of a guided mode extends partly into the cladding, as shown in Fig. 5, another quantity of interest for a step-index fiber is the fractional power flow in the core and cladding for a given mode. As the number approaches cutoff for any particular mode, more of the power of that mode is in the cladding. At the cutoff point, all the optical power of the mode resides in the cladding. For large values of far from cutoff, the fraction of the average optical power residing in the cladding can be estimated by where is the total optical power in the fiber.In an SMF, the geometric distribution of light in the propagating mode is needed when predicting the performance characteristics of these fibers, such as splice loss, bending loss, cutoff wavelength, and waveguide dispersion. Thus, a fundamental parameter of an SMF is the mode-field diameter (MFD), which can be determined from the mode-field distribution of the fundamental fiber mode.17,18,21 MFD is a function of the optical source wavelength, the core radius, and the refractive index profile of the fiber. MFD is analogous to the core diameter in an MMF, except that in an SMF, not all the light that propagates through the fiber is carried in the core. A standard technique to find MFD is to measure the far-field intensity distribution and then calculate the MFD using the Petermann II equation.17,18 where the parameter (with being called the spot size or the mode field radius) is the full width of the far-field distribution. For calculation simplicity, the exact field distribution can be fitted to a Gaussian function. where is the radius and is the field at zero radius, as shown in Fig. 6. Then MFD is given by the width of the optical power. The Gaussian pattern given in Eq. (8) is a good approximation for values of lying between 1.8 and 2.4, which designates the operational region of practical SMFs. An approximation of the relative spot size , which, for a step-index fiber, has an accuracy better than 1% in the range , is given byFig. 6Distribution of light in a single-mode fiber (SMF) above its cutoff wavelength. For a Gaussian distribution, the mode-field diameter is given by the width of the optical power.  Manufacturers typically design an SMF to have values to prevent high cladding losses, but to avoid the possibility of having more than one mode in the fiber. 3.2.Graded-Index Optical Fibers3.2.1.Core index structureIn the graded-index fiber design, the core refractive index continuously decreases with an increasing radial distance from the center of the fiber but is generally constant in the cladding. The most commonly used construction for the refractive-index variation in the core is the power law relationship. Here, is the radial distance from the fiber axis, is the core radius, is the refractive index at the core axis, is the refractive index of the cladding, and the dimensionless parameter defines the shape of the index profile. The index difference for the graded-index fiber is given by The approximation on the right-hand side reduces this expression for to that of the step-index fiber. Thus, the same symbol is used in both cases. For , inside the core, Eq. (10) reduces to the step-index profile . 3.2.2.Graded-index numerical apertureDetermining the NA for graded-index fibers is more complex than for step-index fibers because it is a function of position across the core end face. This is in contrast to the step-index fiber, where NA is constant across the core. Geometrical optics considerations show that light incident on the fiber core at position will propagate as a guided mode only if it is within the local numerical aperture at that point. The local NA is defined as where the axial NA is defined asThus, the NA of a graded-index fiber decreases from NA(0) to zero as moves from the fiber axis to the core-cladding boundary. The number of bound modes in a graded-index fiber is Fiber manufacturers typically choose a parabolic refractive index profile given by . In this case, , which is half the number of modes supported by a step-index fiber (for which ) that has the same value. 3.2.3.Cutoff condition in graded-index fibersSimilar to step-index fibers, in order to eliminate intermodal dispersion, graded-index fibers can be designed as an SMF in which only the fundamental mode is allowed to propagate at the desired operational wavelength. An empirical expression of the parameter at which the second lowest-order mode is cut off for graded-index fibers has been shown to be17,18 Equation (15) shows that, in general, for a graded-index fiber, the value of decreases as the profile parameter increases. It also shows that the critical value of for the cutoff condition in parabolic graded-index fibers () is a factor of larger than for a similar-sized step-index fiber. Furthermore, from the definition of given by Eq. (4), the NA of a graded-index fiber is larger than that of a step-index fiber of comparable size. 3.3.Performance Characteristics of Generic Optical FibersWhen considering the type of fiber to use in a particular biophotonics system application, some performance characteristics that need to be taken into account are optical signal attenuation as a function of wavelength, optical power-handling capability, the degree of signal loss as the fiber is bent, and mechanical properties of the optical fiber. 3.3.1.Attenuation versus wavelengthAttenuation is due to absorption, scattering, and radiative losses of optical energy as light propagates along a fiber. For convenience of power-budget calculations, attenuation is measured in units of decibels per kilometer () or decibels per meter (). A variety of materials are used to make different types of optical fibers. The basic reason for providing such a selection is that each material type exhibits different light-attenuation characteristics in various spectral bands. For example, silica () glass is the principal material used to make conventional solid-core fibers for telecom applications. It has low losses in the 800- to 1600-nm region, but the loss is significantly higher at shorter and longer wavelengths. Thus, as Sec. 4 describes, other fiber types and/or materials are needed for biophotonics applications that use wavelengths outside of the telecom spectral band. 3.3.2.Bend-loss insensitivityAs described in Sec. 4.2.3, standard optical fibers exhibit radiative losses whenever the fiber is bent. For slight bends, this loss is negligible. However, as the radius of curvature decreases, the bending-induced loss exponentially increases and at a certain critical radius, the loss becomes extremely large. Specially designed fibers with an NA moderately higher than that in a conventional SMF are less sensitive to bending loss. Bend-insensitive fibers are commercially available to provide an optimum low bending loss performance at specific operating wavelengths, such as 820 or 1550 nm. These fibers are available with an cladding diameter as standard products. In addition to low bending losses, the smaller outer diameter of these fibers yields a much smaller coil volume compared with a standard cladding diameter when a length of this low-bend-loss fiber is coiled up within a miniature optoelectronic device package or in a compact biophotonics instrument. Section 4.2.3 presents more details on specialty optical fibers that are robust toward bending-induced power losses. Other fiber classes that exhibit low bending-induced losses include HCS fibers (see Sec. 4.4) and various types of PCFs (see Sec. 4.6). 3.3.3.Mechanical propertiesThere are a number of unique mechanical properties of optical fibers that make them attractive for biomedical applications. One important mechanical factor is that optical fibers consist of a thin highly flexible medium, which allows various minimally invasive medical treatments or diagnostic procedures to take place in a living body. As described in Sec. 5, these procedures can include endoscopy, bronchoscopy, cardiovascular surgery, and microsurgery. Several factors can affect the mechanical integrity of optical fibers used in biomedical environments.20–23 Among these effects are potential strength degradations due to repeated sterilization processes, long-term exposure to UV light, damage to fibers and connectors due to improper handling, and exposure to extremely high optical power levels. A second important mechanical characteristic is that by monitoring or sensing some intrinsic physical variation of an optical fiber, such as elongation or refractive index changes, one can create fiber sensors to measure many types of external physical parameter changes. For example, if the external parameter elongates the fiber or induces refractive index changes, this effect can modulate the intensity, phase, polarization, wavelength, or transit time of light in the fiber. The degree of light modulation is then a direct measure of changes in the external physical parameter. For biophotonics applications, the external physical parameters of interest include pressure, temperature, stress, strain, and the molecular composition of a liquid or gas surrounding the fiber. Section 5.8 gives some examples of these biosensor applications. 3.3.4.Optical power-handling capabilityAlthough in some biomedical photonics applications, such as imaging and fluorescence spectroscopy, the optical fibers carry power levels of , in other situations, the fibers must be able to transmit optical power levels of 10 W and higher. A principal application is laser surgery, which includes bone ablation, cardiovascular surgery, cosmetic surgery, dentistry, dermatology, eye surgery, and oncology surgery. Hard-clad silica optical fibers with fused silica cores that have very low contaminants are described in Sec. 4.4. These fibers are capable of conducting very high optical power from either a continuous wave (CW) or pulsed laser. Other fibers that are capable of transmitting high optical power levels include conventional hollow-core fibers (see Sec. 4.5), PCFs (see Sec. 4.6), and germanate () glass fibers (see Sec. 4.9). The challenge is the launching of high power levels into a fiber. Artifacts such as dust or scratches on the end face of the fiber can form absorption sites that generate high temperature levels at the fiber tip. In standard connectors where the fibers are glued into the connector housing, these high temperatures cause the surrounding epoxy to break down and give off gases. These gases burn onto the tip of the fiber, causing catastrophic damage to the fiber and the connector. To handle high power levels, various manufacturers have developed special fiber optic patch cords that have carefully prepared fiber end faces and specially designed fiber optic connectors that greatly reduce the susceptibility to thermal damage.22,23 4.Optical Fiber Types and Materials for Use in BiophotonicsThe optical power levels that have to be detected or transmitted in a biophotonics process can vary by ten orders of magnitude depending on the particular application. The detected light levels of interest can be in the nanowatt range for spectroscopic applications, whereas optical power being delivered to a biological specimen can be as high as several watts during light therapy sessions or during laser surgery. Consequently, certain fiber types need to be implemented for specific uses in different spectral bands. The basic fiber structures that can be used in biophotonics applications include conventional solid-core silica fibers, specialty solid-core fibers, DCFs, HCS fibers, conventional hollow-core fibers, PCFs, plastic fibers, side-emitting and side-firing fibers, middle-infrared fibers, and fiber bundles. This section describes the characteristics of these classes of fibers as they apply to biophotonics systems. 4.1.Conventional Optical FibersAs a result of extensive development work for telecom networks, conventional solid-core silica-based optical fibers are highly reliable and are available in a variety of core sizes. These fibers are used worldwide in telecom networks and in many biophotonics applications. Figure 7 shows the optical signal attenuation per kilometer for a standard -doped silica fiber as a function of wavelength and photon energy.17 The shape of the attenuation curve is due to three factors. Intrinsic material absorption due to electronic absorption bands causes high attenuations in the UV region for wavelengths . The Rayleigh scattering effect then starts to dominate the attenuation for wavelengths , but diminishes rapidly because of its behavior. Intrinsic absorption associated with atomic vibration bands in the basic fiber material increases with wavelength and is the dominant attenuation mechanism in the IR region above . As shown in Fig. 7, these attenuation mechanisms produce a low-loss region in silica fibers in the spectral range of 700 to 1600 nm, which matches the low-absorption biophotonics window illustrated in Fig. 1. The attenuation spike around 1400 nm is due to absorption by residual water ions in the silica material. Greatly reducing these ions during the manufacturing process results in a special low-water-content or low-water-peak fiber in which the attenuation spike has been greatly reduced. Conventional optical fibers fall into MMF and SMF categories. Because an SMF sustains only one mode of propagation, whereas MMFs contain many hundreds of modes, an MMF can carry more optical power than an SMF. However, an SMF is needed for applications that deal with coherence effects between propagating light beams. Commercially available MMF can be purchased with standard core diameters of 50, 62.5, 100, , or larger. As Sec. 5 describes, these MMFs are used in areas such as laser or light-emitting diode (LED) light delivery, biostimulation, optical fiber probes, and phototherapy. SMFs have core diameters around , the exact value depending on the wavelength of interest. Applications of SMFs include biomedical fiber sensors used in endoscopes or catheters, in imaging systems, such as optical coherence tomography (OCT) (see Sec. 5.2), and in healthcare sensor systems based on optical fiber sensors. 4.2.Specialty Solid-Core FibersSpecialty solid-core fibers are custom-designed for functions such as manipulating lightwave signals to achieve some type of optical signal-processing function, extending the spectral operating range of the fiber, or sensing variations of a physical parameter, such as temperature or pressure. Incorporation of such features into an optical fiber is achieved through either material or structural variations. For biophotonics applications, the main specialty fiber types are photosensitive fibers for creating internal gratings, fibers resistant to darkening from UV light, bend-loss-insensitive fibers for circuitous routes inside bodies, and polarization-preserving optical fibers for imaging and for fluorescence analyses in spectroscopic systems. 4.2.1.Photosensitive optical fiberA photosensitive fiber is designed so that its refractive index changes when it is exposed to UV light. For example, doping the fiber core material with germanium and boron ions may provide this sensitivity. The main application for such a fiber is to create a short fiber Bragg grating (FBG) in the fiber core, which is a periodic variation of the refractive index along the fiber axis.24–26 This index variation is illustrated in Fig. 8, where is the refractive index of the core of the fiber, is the index of the cladding, and is the period of the grating, that is, the spacing between the maxima of the index variations. If an incident optical wave at a wavelength (which is known as the Bragg wavelength) encounters a periodic variation in the refractive index along the direction of propagation, will be reflected back if the following condition is met: . Here, is the effective refractive index, which has a value falling between the refractive indices of the core and of the cladding. When a specific wavelength meets this condition, this wavelength will get reflected and all others will pass through. FBGs are available in a selection of Bragg wavelengths with spectral reflection bandwidths at a specific wavelength varying from a few picometers to tens of nanometers. As described in Sec. 5.9, an important biophotonics application of an FBG is to sense a variation in a physical parameter, such as temperature or pressure. For example, an external factor, such as strain, will slightly stretch the fiber. This stretching will lengthen the period of the FBG and, thus, will change the value of the specific reflected wavelength. Similarly, rises or drops in temperature will lengthen or shorten the value of , respectively, thereby changing the value of . 4.2.2.Fibers resistant to UV-induced darkeningConventional solid-core silica fibers are highly sensitive to UV light. The intrinsic attenuation is higher in the UV region compared to the visible and NIR spectra, and there are additional losses due to UV-absorbing material defects, which are created by high-energy UV photons. These additional UV-induced darkening losses are known as solarization and occur strongly at wavelengths . Thus, although newly manufactured conventional silica fibers offer low attenuation in the 214- to 254-nm range, upon exposure to an unfiltered deuterium lamp, the transmission of these fibers drops to of the original value within a few hours of continuous UV irradiation. Consequently, conventional silica optical fibers can be used only for applications above . However, recently, special glass material processing techniques, such as the use of pure silica fibers with a low water concentration, infusion of hydrogen into the silica core, or fluorine doping of the cladding, have resulted in fibers that exhibit lower UV sensitivity below 260 nm.27–29 When these types of fibers are exposed to UV light, the attenuation first increases rapidly and then stabilizes to an asymptotic value. The exact asymptotic value and the time to reach the plateau depend on the fiber type from specific manufacturers and on the UV wavelength. Shorter wavelengths result in higher attenuation changes and it takes longer to reach the asymptotic value. For example, Polymicro Technologies reported UV exposure test results from several of their fibers.27 Those tests consisted of launching light from a high-intensity deuterium lamp into a 2-m length of fiber for 4 h. The losses were measured at six different UV wavelengths ranging from 214 to 330 nm. The increase in attenuation and the time needed to reach loss equilibrium for the 2-m FBPI fiber® was as follows for 214, 254, and 330 nm wavelengths:

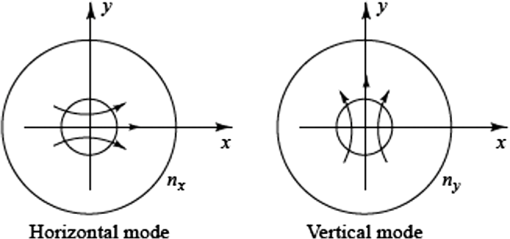

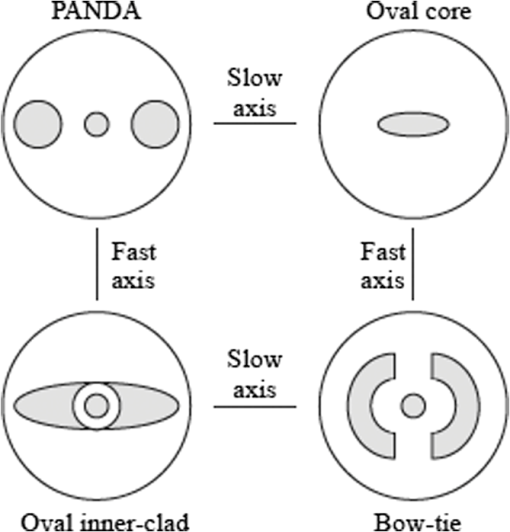

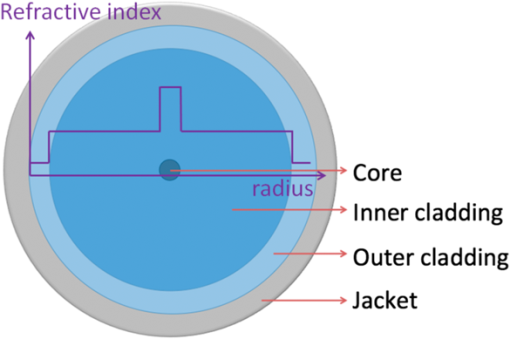

Solarization-resistant fibers are typically available with core diameters ranging from 50 to . When using these types of fibers, they should first be exposed to UV radiation for 5 min or more (depending on the desired wavelength being used) to establish a loss equilibrium. 4.2.3.Bend-loss-insensitive fiberIn many medical applications of optical fibers within a living body, the fibers need to follow a sinuous path with sharp bends through arteries that snake around bones and organs. Special attention must be paid to this situation, because standard optical fibers exhibit radiative losses whenever the fiber undergoes a bend with a finite radius of curvature. For slight bends, the radiative loss is negligible. However, as the radius of curvature decreases, the losses exponentially increase until at a certain critical radius the losses become extremely large. Thus, special bend-loss-insensitive fibers need to be used for certain implementations. The expansion of optical fiber links directly to homes and businesses has led the telecom industry to develop bend-loss-insensitive fibers that can tolerate numerous sharp bends for indoor installations at operating wavelengths between 960 and 1550 nm.30–32 These same types of fibers can also be used for medical applications. Such fibers have a moderately higher NA than in a standard telecom SMF. Increasing the NA reduces the sensitivity of the fiber to bending loss by confining the optical power more tightly within the core than in a conventional SMF. Bend-loss-insensitive fibers are commercially available from a variety of optical fiber manufacturers. These fibers are offered with either an 80- or a cladding diameter as standard products. The reduced-cladding fiber results in a 40% volume size compared with a cladding when a fiber length is coiled up within a miniature optoelectronic device package or in a biophotonics instrument. As an example, consider the the HI-1060 FLEX® fiber from Corning, Inc. (Corning, New York) designed for use in the 960- to 1665-nm range. This fiber has a lower single-mode cutoff wavelength (), a nominally 50% higher index difference value , and a 25% higher NA (0.20 versus 0.16) than other fibers. The higher NA of low-bend-loss fibers allows an improved coupling efficiency from laser diode sources and to planar waveguides. For a bend radius , the bending-induced loss is negligibly small. For fiber loops with a 10-mm bend radius, the bending loss is per loop across the entire 960- to 1665-nm operating range. A factor to keep in mind is that a mode-mismatch loss can be induced when interconnecting these fibers with standard SMFs due to the smaller MFD of low-bend-loss fibers. However, carefully made splices between these different fibers typically result in losses . 4.2.4.Polarization-maintaining fiberIn a conventional SMF, the fundamental mode consists of two independent orthogonal polarization modes.17,18 These modes may be arbitrarily chosen as the horizontal and vertical polarizations in the direction and direction, respectively, as shown in Fig. 9. In general, the electric field of the light propagating along the fiber is a linear superposition of these two polarization modes and depends on the polarization of the light at the launching point into the fiber. In ideal fibers with perfect rotational symmetry, the two modes are degenerate with equal propagation constants (, where and are the effective refractive indices along the and axes, respectively), and any polarization state injected into the fiber will propagate unchanged. In actual fibers, there are imperfections, such as asymmetrical lateral stresses, noncircular cores, and slight variations in refractive-index profiles. These imperfections break the circular symmetry of the ideal fiber and lift the degeneracy of the two modes. The modes then propagate with different phase velocities, and the difference between their effective refractive indices is called the fiber birefringence. If light is injected into the fiber so that both modes are excited, then one mode will be delayed in phase relative to the other as they propagate. When this phase difference is an integral multiple of , the two modes will beat at this point and the input polarization state will be reproduced. The length over which this beating occurs is the fiber beat length, . In conventional fibers, the small degrees of random imperfections in the core will cause the state of polarization to fluctuate as a light signal propagates through the fiber. In contrast, polarization-maintaining fibers have a special core design that preserves the state of polarization along the fiber with little or no coupling between the two modes. Figure 10 illustrates the cross-sectional geometry of four different polarization-maintaining fibers. The light circles represent the cladding and the dark areas are the core configurations. The goal in each design is to use stress-applying parts to create slow and fast axes in the core. Each of these axes will guide light at a different velocity. Crosstalk between the two axes is suppressed so that polarized light launched into either of the axes will maintain its state of polarization as it travels along the fiber. These fibers are used in special applications, such as fiber optic sensing and interferometry, where polarization preservation is essential.33,34 A further structural refinement uses the bow-tie geometry shown in Fig. 10 in order to create an extreme birefringence in a fiber. Such a birefringence allows one and only one polarization state of the fundamental mode to propagate with all other polarization modes being greatly suppressed. In these fibers, single-polarization guidance occurs in only a limited wavelength range of . Outside of that spectral range, either both of the polarization states or no light at all may be guided. These fibers are used in special fiber optic biosensing applications where it is desirable to monitor a single state of polarization. 4.3.Double-Clad FibersA DCF has found widespread use in constructing optical fiber lasers and now is being used in the medical field for imaging systems, such as endoscopy.35–38 More details on these applications are given in Secs. 5.3 and 5.4. As indicated in Fig. 11, a DCF consists of an inner cladding, an outer cladding, and a core region arranged concentrically. Typical dimensions of a commercially available DCF are a core diameter, an inner cladding diameter of , and an outer cladding with a diameter. Light transmission in the core region is single-mode, whereas in the inner cladding, it is multimode. The typical index of a DCF for biomedical applications is decreasingly cascaded from the core center to the cladding boundary. The integration of both single-mode and multimode transmissions allows using a single optical fiber for the delivery of the illumination light (using the single-mode core) and the collection of the tissue-reflected light (using the multimode inner cladding). 4.4.Hard-Clad Silica FibersA HCS optical fiber is a multimode design that consists of a silica glass core surrounded by a hard thin plastic cladding. The hard cladding increases fiber strength and reduces static fatigue in humid environments. These fibers also feature bend insensitivity, long-term reliability, ease of handling, and resistance to harsh chemicals.39,40 Core diameters of commercially available HCS fibers range from 200 to . Table 1 lists some performance parameters of three selected HCS fibers. A common HCS fiber for industrial and medical applications has a core diameter of and a cladding diameter of , which results in a very strong optical fiber with low attenuation ( at 820 nm), an NA of 0.39, negligible bending-induced loss for bend diameters , and an extremely high core-to-clad ratio to enable efficient light coupling into and out of the fiber. The fibers are available in both high and low content for operation in the UV, visible, and NIR regions. The mechanical, optical, and structural properties of HCS fibers are especially useful in applications like laser delivery, endoscopy, photodynamic therapy (PDT), and biosensing systems. Table 1General specifications of selected hard-clad silica (HCS) fibers.