|

|

1.IntroductionOcular losses arising from congenital deformities, cancer, or trauma1–6 cause aesthetic damage, as they result in asymmetry and, consequently, facial disfigurement.1–4,7–10 The ocular prosthesis is a rehabilitative option that is safe, generally aesthetically pleasing, and satisfactory from a treatment point of view.10–13 Although it does not restore vision, it does restore the face’s aesthetic appearance, beautifying the face, where the patient’s appearance had been compromised.5 The material of choice for fabrication of ocular prostheses is thermopolymerizable acrylic resin. The acrylic resin for the artificial sclera contains white pigments to approximate the color of a natural sclera. A colorless acrylic resin is used to cover sketches of blood vessels and the artificial iris, which remain adhered to the artificial sclera.1–3,5,6 Ocular prostheses are only remain effective for a short period of time, ranging from one to five years.1,5 They need to be remade mainly because of changes in the artificial iris color. The artificial iris color is a cosmetic characteristic that is important to the patient, and one that should be observed shortly after the iris is made, as well as during use.14,15 Some authors suggest that the chromatic changes in artificial irises come not simply from degradation caused by exposure to environmental factors, but rather mainly from the process of polymerization in the acrylic resin that covers over the paint.16–20 With the aim of increasing the stability of the prosthesis color in the face of aging caused by the artificial iris paint exposure to environmental factors and minimizing the effects of the polymerization process, the use of prefabricated caps has won favor over other techniques of ocular prosthesis production.17,21–24 In conjunction with this technique, a protective varnish can be applied over the paint of the artificial iris to reduce chromatic changes.2,17 In light of the aforementioned factors, this study’s goal was to analyze the stability of the color of artificial iris buttons obtained by conventional painting techniques relative to those produced by inverted painting on a prefabricated cap or by conventional painting under the prefabricated cap, with or without the use of a protective varnish, after application of colorless acrylic resin over the paint. 2.Materials and Methods2.1.Sample PreparationWe obtained samples that were produced by way of the above techniques of ocular iris button manufacture and divided them into six groups (Table 1). We made 60 samples simulating ocular prostheses with brown irises. The manufacturing techniques for the ocular iris’ button were the conventional technique (pressing the acrylic resin onto a painted disk of paper, PE), the technique involving a prefabricated cap (the base of the ocular cap positioned over the painting of the paper disk, CA) and inverted painting (the base of the painted ocular iris, PI). We made 20 samples with each technique and applied protective varnish to half of the samples made by each technique (PEV, PIV, and CAV), leaving the other half unvarnished (PE, PI, and CA) and producing 10 samples in each final group. Table 1Analysis of variance (ANOVA) of the color changes after polymerization.

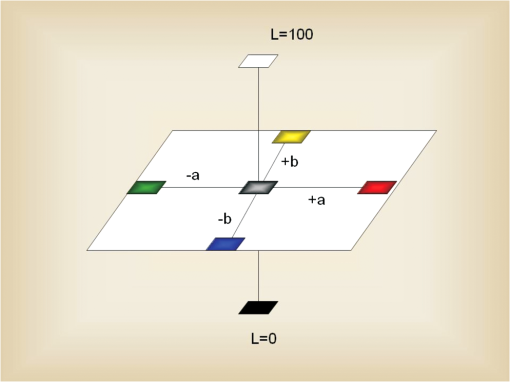

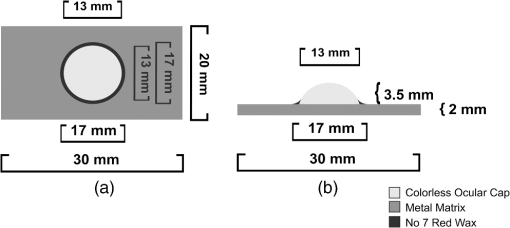

We made the samples using modified metal matrices according to the technique established by Goiato et al.23 These matrices were rectangular, measuring 30 mm length, 20 mm width, and 2 mm thickness, with a 13-mm-diameter circular demarcation in the center (Fig. 1). We positioned colorless ocular caps onto the center of the matrices, on top of the demarcation. The metal matrix and colorless cap unit was placed in their own muffle for polymerization in a microwave oven. Fig. 1A schematic representation of the dimensions of the metal matrix showing the ocular cap’s position from above (a) and from the side (b).  Shortly after the final press of the plaster, we withdrew each unit from the muffle, and we filled the region corresponding to the prefabricated ocular cap (Artigos Odontológicos Clássico Ltda., SP, Brazil) with extra-hard silicon (Zhermack, Italy) and filled the region corresponding with the matrix with thermopolymerizable N.1 acrylic resin (Artigos Odontológicos Clássico Ltda., SP, Brazil) and placed the unit in a hydraulic press (Midas Dental Products Ltda., SP, Brazil) with a force of 1.2 kgF for 2 min. We polymerized the resin in a microwave oven (Brastemp, SP, Brazil) at 60% maximum power (1400 W) for 3 min.23,24 After polymerizing the resin, we opened the muffle again and removed the silicon that had filled the mold of the ocular cap to be pressed into each artificial iris button. We produced the artificial iris by painting a brown-colored oil paint (Acrilex Tintas Especiais SA, SP, Brazil) onto disks of black cardboard or onto the planar surface of the ocular cap (inverted painting), both with a diameter of 13 mm, during the same period and under the same lighting conditions, using an n.0 ref. 175 brush (Tigre S.A., SP, Brazil). To accelerate drying of the oil paint, we added a cobalt drying agent (Acrilex Tintas Especiais SA, SP, Brazil) corresponding with 30% in weight of the quantity of oil paint used. We conducted the final drying by using direct exposure to a 250-W, 130 E26-V infrared light source (Empalux Ltda., PR, Brazil) at a 30-cm distance from the disks for 2 h.11 After completing this process, we applied three light layers of waterproof paint-protecting varnish spray (Acrilex Tintas Especiais SA, SP, Brazil) to the artificial irises from the PEV, CAV, and PIV groups. To obtain the artificial eye buttons for the samples from groups PE and PEV, we pressed acrylic resin onto the painted surface of the paper disk. For this process, we fixed the painted disks with a liquid adhesive (J-305, Monopoly Syrup; Factor II Inc., Lakeside, Arizona)18 onto the center of a thermopolymerizable N.1 acrylic resin plate (Artigos Odontológicos Clássico Ltda., SP, Brazil). We pressed a colorless acrylic resin specifically made for ocular prostheses onto the disks. We inserted the resin into the molds contained in the muffles, so we could then press them in a hydraulic press with a force of 1.2 kgF. We polymerized the resin in a microwave oven (Brastemp, SP, Brazil) at 60% maximum power (1400 W) for 3 min.11 We obtained the buttons of the artificial irises from the samples in groups CA and CAV by fixing the painted area of the cardboard disks onto the base of the ocular caps, using liquid adhesive (J-305, Monopoly Syrup; Factor II Inc., Lakeside, Arizona).18 Next we fixed the iris buttons using the same adhesive to the center of a thermopolymerizable N.1 acrylic resin plate. On the interface between the iris button and the N.1 acrylic resin plate, we pressed on thermopolymerizable colorless acrylic resin, and polymerized it in a microwave oven under the same conditions described above.11 We obtained the artificial iris buttons from the samples in groups PI and PIV by painting the iris on the base of the ocular cap (inverted painting technique), then fixing it with liquid adhesive (J-305, Monopoly Syrup; Factor II Inc., Lakeside, Arizona) 20 onto the center of the N.1 acrylic resin plate. On the interface between the iris button and the thermopolymerizable N.1 acrylic resin plate, we pressed and polymerized thermopolymerizable colorless acrylic resin, as previously described.11 2.2.Spectrophotometric Analysis of Color ChangeOnce this procedure was completed, initial color readings were taken using visible ultraviolet reflect spectrophotometer, across the diameter of the sample. For the measurement of a color difference, the uniformed color space color system, which is closer to the human sensation, was used to show the color difference quantitatively. Chromatic and whiteness/brightness changes were evaluated by refraction spectrophotometer (UV-2450; Shimadzu Corp, Kyoto, Japan), with wavelength ranging from 780 (at the beginning) to 380 (at the end); and color changes being calculated according to the International Commission on Illumination (CIE) standards using the L*a*b* system with the standard illuminant D65.2,11–13 The spectrophotometer (UV-2450; Shimadzu Corp, Kyoto, Japan) has a ceramic emission source in which the light beams are transmitted toward the sample. In the refraction spectrometry, the monochromatic color focus on the surface of sample and part of the light beam is absorbed and the other is reflected.11 The amount of reflected light is captured by a photocell, which translates its wavelength into electrical signals, and is further captured by the computer system (UVPC Optional Color Analysis software package, Shimadzu Corp, Kyoto, Japan). This color measurement software provides the CIE L*a*b* color systems, where L* (or ) shows the lightness, and the other two parameters (a* and b*; or and ) show the chromaticity.13 The CIE L*a*b* system allows color perception to be specified in three-dimensional (3-D) space (Fig. 2) by comparing the color of the surface of sample with the control group of the equipment, through a wavelength versus refraction index. In this 3-D color space, the three axes are namely L*, a*, and b*. The “” value is known as whiteness or brightness of an object and ranges from 0 (black) to 100 (perfect white).13 The “” value represents the quantity of red (positive values) and green (negative values), while the “” value represents the quantity of yellow (positive values) and blue (negative values). The “” and “” parameters coexist on the same plane within this 3-D space (Fig. 2). Color variation between two points was calculated using the CIE L*a*b* system, based on the following formula: . The samples were positioned in the same way using a black covered metal device that was created by the authors and adapted to the spectrophotometer (UV-2450; Shimadzu Corp, Kyoto, Japan) for use in this study; this device was designed to standardize the reading area and prevent color variation.13 3.ResultsTables 1 and 2 show the results obtained. All of the factors we evaluated influenced the values for the chromatic stability of the artificial iris buttons after polymerization (Table 1; ). Table 2Mean values (with standard deviations) for color change (ΔE) in each group.

Note: Different letters denote a significant difference between the groups by Tukey’s test. Significantly less chromatic change was observed in the samples in the PEV and CAV groups than in their no-varnish counterparts in the PE and CA groups (Table 2). Samples made using the PI technique with varnish (PIV group) had the lowest values, differing significantly from all groups except the PI group, which had the second lowest value. Meanwhile, samples made using the CA technique without varnish (CA group) had significantly higher values than all other groups, including the CAV group, which had the second highest values and differed significantly from all other groups. 4.DiscussionThe present results demonstrated that both technique and varnish had significant effects on chromatic change for all of the factors analyzed (Table 1). A significant interaction of technique and varnish on chromatic change was also observed. The results obtained verify that the color derivative () for all of the samples was greater than zero in both periods of measurement, as indicated by spectrophotometric analysis of color change (Table 2). The traditional technique of manufacturing ocular prostheses involves painting the iris onto cardboard paper and pressing acrylic resin directly onto this painting. Brown oil paint, as used in this study, has been characterized as more stable than other colors owing to the presence of opacifiers (zinc oxide) and mineral components (linseed oil), which form a resistant, irreversible, and transparent film.11,12 Nevertheless, a color change was observed. The observed color changes may be due to polymerization of the materials, paint, and resin. There may have been an interaction between the components underlying the change in color observed in samples from groups PE and PEV. Previous studies have demonstrated that staining of artificial eyes occurs mainly after the colorless acrylic resin has been polymerized.11,12 In order to minimize this effect, we used a paint-finishing varnish. With the PE technique in particular, we observed more change in color after polymerization in the absence of varnish (PE group) than in the presence of varnish (PEV group). Thus paint-protecting varnish may form a protective film over the iris paint that minimizes the reaction between residual monomers and the oil paint’s polymer components, thereby improving color stability. Using prefabricated caps should impede the residual monomer’s action on iris paint, and thus should reduce color change. However, we found that the samples made with caps (CA and CAV) exhibited the most chromatic change than samples made without them. To glue the prefabricated cap onto the unit of N1 resin and the iris painting on cardboard, we used Monopoly Syrup (J-305). We suspect that using this adhesive directly on the painting may have destabilized the color. The adhesive, composed of a methyl methacrylate monomer, could have reacted with the polymer components of the oil paint, thus altering the color. We also observed that application of paint-protecting varnish (CAV) significantly reduced color instability compared with similarly made samples without varnish (CA) However, even with this reduction, color change remained high relative to groups of samples made without prefabricated ocular caps (PE and PEV). We observed the greatest color stability following polymerization in the samples that were made using the inverted painting technique, in which the iris paint is applied directly onto the base of the ocular cap. We also used Monopoly Syrup to attach the painted ocular cap to the N1 acrylic resin bar. However, we applied the adhesive to the base of the cap, below the painting. We believe that the reaction of the adhesive with the paint’s polymer components was restricted to the final layer of paint, on the interface between the N1 resin bar and the iris painting and therefore did not interfere much with color stability. Using varnish on samples prepared using the inverted painting technique did not significantly affect color stability, presumably because it was also applied to the interface of the N1 resin bar and the iris painting. In reviewing the literature about color change of polymer materials, we found several studies, such as those by Mundim et al.21 and Goiato et al.,2,11,12 that defined color change values () greater than 3.7 as clinically unsatisfactory. Here, clinically unsatisfactory values were observed during the initial processing involved in manufacturing the ocular prosthesis for the CA and CAV groups. 5.ConclusionsWithin the limitations of our study, we conclude that artificial iris button production using the PI technique yields the least color change of the three techniques examined, with both the PI and PE techniques yielding clinically acceptable values. Furthermore, we conclude that the application of paint-protecting varnish onto the iris painting increases color stability with all three of the techniques studied. ReferencesM. Filié Haddadet al.,

“Color stability of maxillofacial silicone with nanoparticle pigment and opacifier submitted to disinfection and artificial aging,”

J. Biomed. Opt., 16

(9), 095004

(2011). http://dx.doi.org/10.1117/1.3625401 JBOPFO 1083-3668 Google Scholar

M. C. Goiatoet al.,

“Alteration of blue pigment in artificial iris in ocular prosthesis: effect of paint, drying method and artificial aging,”

Cont. Lens Anterior Eye, 34

(1), 22

–25

(2011). http://dx.doi.org/10.1016/j.clae.2010.10.005 1367-0484 Google Scholar

J. S. SongJ. OhS. H. Baek,

“A survey of satisfaction in anophthalmic patients wearing ocular prosthesis,”

Graefes Arch. Clin. Exp. Ophthalmol., 244

(3), 330

–335

(2006). http://dx.doi.org/10.1007/s00417-005-0037-0 GACODL 0721-832X Google Scholar

K. ChinC. B. MargolinP. T. Finger,

“Early ocular prosthesis insertion improves quality of life after enucleation,”

Optometry, 77

(2), 71

–75

(2006). http://dx.doi.org/10.1016/j.optm.2005.12.012 OVSCET 1040-5488 Google Scholar

M. C. Goiatoet al.,

“Patient satisfaction with maxillofacial prosthesis: literature review,”

J. Plast. Reconstr. Aesthet. Surg., 62

(2), 175

–180

(2009). http://dx.doi.org/10.1016/j.bjps.2008.06.084 1748-6815 Google Scholar

M. C. Goiatoet al.,

“Microphthalmia and retinoblastoma: observations and case reports,”

J. Ophthalmic Prosthe, 13

(1), 43

–46

(2008). Google Scholar

M. KohlhaasD. Schulz,

“The complex facial prosthesis: the value of bone-anchored maxillofacial prostheses in the treatment of extensive loss of facial tissue,”

Rev. Stomatol. Chir Maxillofac., 102

(5), 261

–265

(2001). Google Scholar

M. C. Goiatoet al.,

“Psychosocial impact on anophthalmic patients wearing ocular prosthesis,”

Int. J. Oral Maxillofac. Surg., 42

(1), 113

–119

(2013). http://dx.doi.org/10.1016/j.ijom.2012.05.028 IJOSE9 0901-5027 Google Scholar

M. D. Canadaset al.,

“Color stability, surface roughness, and surface porosity of acrylic resins for eye sclera polymerized by different heat sources,”

J. Prosthodont., 19

(1), 52

–57

(2010). http://dx.doi.org/10.1111/j.1532-849X.2009.00522.x JPORCN 1059-941X Google Scholar

K. RaizadaD. Rani,

“Ocular prosthesis,”

Cont. Lens Anterior Eye, 30

(3), 152

–162

(2007). http://dx.doi.org/10.1016/j.clae.2007.01.002 1367-0484 Google Scholar

A. Fernandeset al.,

“Color alteration in paint the irises for ocular prostheses,”

Braz. Oral Res., 23

(4), 386

–392

(2009). http://dx.doi.org/10.1590/S1806-83242009000400007 1806-8324 Google Scholar

M. C. Goiatoet al.,

“Evaluation of the color stability of two techniques for reproducing artificial irides after microwave polymerization,”

J. Appl. Oral Sci., 19

(3), 200

–203

(2011). http://dx.doi.org/10.1590/S1678-77572011000300004 JAOSBM 1678-7765 Google Scholar

A. Morenoet al.,

“Influence of different disinfecting solutions on the color change of artificial irises used in ocular prostheses,”

Color Res. Appl.,

(2012). http://dx.doi.org/10.1002/col.21754 CREADU 0361-2317 Google Scholar

S. F. Erpf,

“Comparative features of plastic and/or glass in artificial eye construction,”

Arch Ophthalmol., 50

(6), 737

–744

(1953). http://dx.doi.org/10.1001/archopht.1953.00920030748009 AROPAW 0003-9950 Google Scholar

N. A. Dyer,

“The artificial eye,”

Aust. J. Ophthalmol., 8

(4), 325

–327

(1980). http://dx.doi.org/10.1111/j.1442-9071.1980.tb00293.x AJOHBL 0310-1177 Google Scholar

S. Taicheret al.,

“Modified stock-eye ocular prosthesis,”

J. Prosthet. Dent., 54

(1), 95

–98

(1985). http://dx.doi.org/10.1016/S0022-3913(85)80079-2 JPDEAT 0022-3913 Google Scholar

B. Reitemeieret al.,

“Optical modeling of extraoral defects,”

J. Prosthet. Dent., 91

(1), 80

–84

(2004). http://dx.doi.org/10.1016/j.prosdent.2003.10.010 JPDEAT 0022-3913 Google Scholar

I. I. Artopoulouet al.,

“Digital imaging in the fabrication of ocular prostheses,”

J. Prosthet. Dent., 95

(4), 327

–330

(2006). http://dx.doi.org/10.1016/j.prosdent.2006.01.018 JPDEAT 0022-3913 Google Scholar

A. FernandesM. C. GoiatoD. M. Santos,

“Effect of weathering and thickness on the superficial microhardness of acrylic resin and ocular button,”

Cont. Lens Anterior Eye, 32

(6), 283

–287

(2009). http://dx.doi.org/10.1016/j.clae.2009.09.001 1367-0484 Google Scholar

C. Y. LungB. W. Darvell,

“Minimization of the inevitable residual monomer in denture base acrylic,”

Dent. Mater., 21

(12), 1119

–1128

(2005). http://dx.doi.org/10.1016/j.dental.2005.03.003 DEMAEP 0109-5641 Google Scholar

F. M. Mundimet al.,

“Influence of artificial accelerated ageing on the colour stability of paints used for ocular prosthesis iris painting,”

Gerodontology, 29

(2), e312

–e317

(2012). GRDND6 0734-0664 Google Scholar

R. C. ReisR. B. DiasJ. Carvalho,

“Evaluation of iris color stability in ocular prosthesis,”

Braz. Dent. J., 19

(4), 370

–374

(2008). http://dx.doi.org/10.1590/S0103-64402008000400015 0103-6440 Google Scholar

M. C. Goiatoet al.,

“Influence of investment, disinfection, and storage on the microhardness of ocular resins,”

J. Prosthodont., 18

(1), 32

–35

(2009). http://dx.doi.org/10.1111/j.1532-849X.2008.00372.x JPORCN 1059-941X Google Scholar

M. C. Goiatoet al.,

“Chromatic stability of acrylic resins of artificial eyes submitted to accelerated aging and polishing,”

J. Appl. Oral Sci., 18

(6), 641

–645

(2010). http://dx.doi.org/10.1590/S1678-77572010000600018 JAOSBM 1678-7765 Google Scholar

|